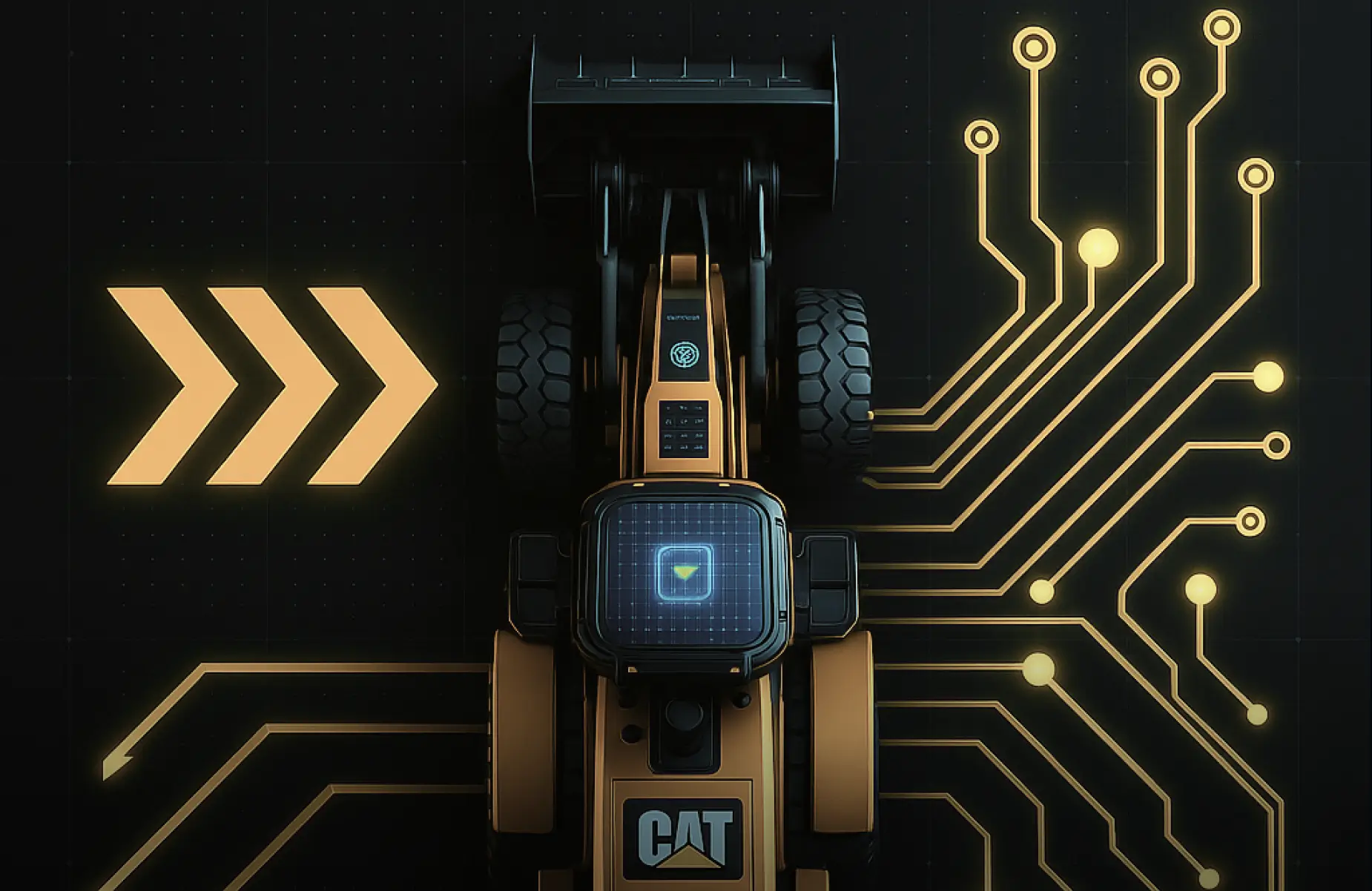

MineStar™ Terrain

The benefits of MineStar™ Terrain for your mine

- High-precision machine guidance for drilling, loading, and leveling tasks.

- Reduction in over-digging, rework, and material waste.

- Improved productivity and quality of execution.

- Real-time monitoring of progress against plans.

- Visualization of deviations, instant adjustments in the cab.

- Better coordination between planning, geology, and execution.

Our complementary optimization solutions