Downtime Analysis & Fleet Performance

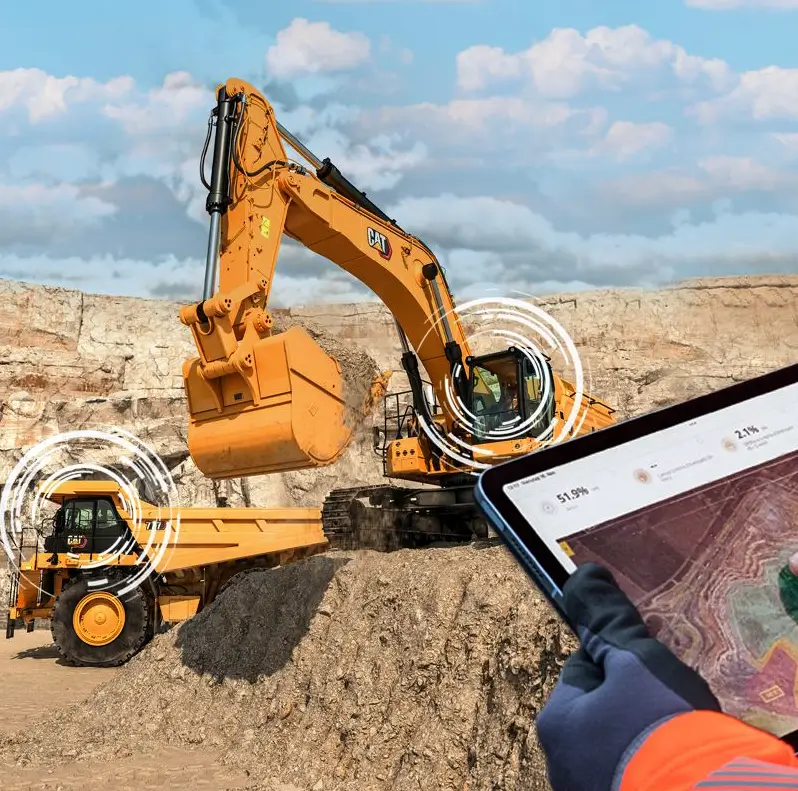

Regain control over your fleet's performance

At Neemba, we transform your fleet data into actionable insights. Using a comprehensive approach that combines telematics, field analysis, and technical expertise, we reveal the real causes of productivity losses and work with you to develop an operational optimization plan.

What we analyze:

- Planned and unplanned downtime.

- Causes of recurring failures.

- Actual availability vs. target availability.

- Useful time vs. idle time.

- Fuel consumption, MTBF, MTTR, machine efficiency.

Our tools:

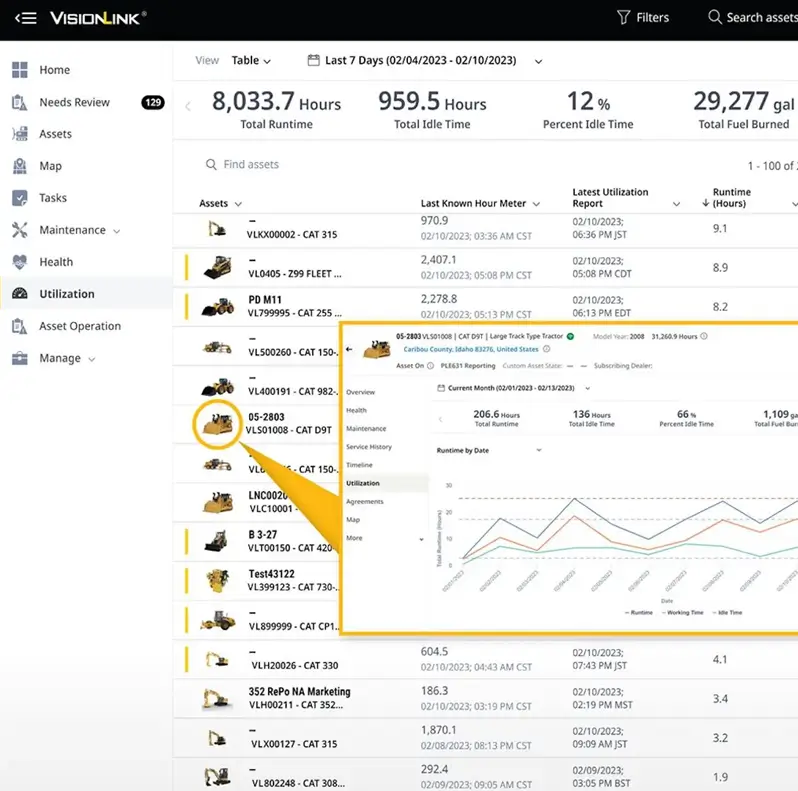

- Onboard telematics (Cat® Product Link™, VisionLink®, etc.).

- Analysis of machine history, maintenance reports.

- Field assessment with your teams.

- Custom benchmarks and KPIs.

Eliminate invisible losses. Unlock new performance.

Les données de votre flotte ont beaucoup à dire. En les analysant en profondeur, vous identifiez les machines les plus critiques, optimisez la maintenance, et pilotez des décisions stratégiques éclairées : remplacements, reconfigurations, locations, etc.

Nos experts vous accompagnent de A à Z, avec des outils professionnels et une lecture terrain orientée action.

Measurable benefits from the very first weeks

- Reduction in unplanned downtime.

- Improved machine availability and efficiency.

- Informed decisions on fleet management.

- More accurate maintenance planning.

- Optimized cost per hour or per ton.

- Better coordination between maintenance, production, and technical management.

Make your data speak. Empower your operations.

Notre démarche s’appuie sur les standards Caterpillar et sur l’expertise terrain de nos ingénieurs application.

Vous ne recevez pas seulement des chiffres : vous obtenez des recommandations concrètes, applicables immédiatement pour améliorer la performance de votre flotte.

Our other services