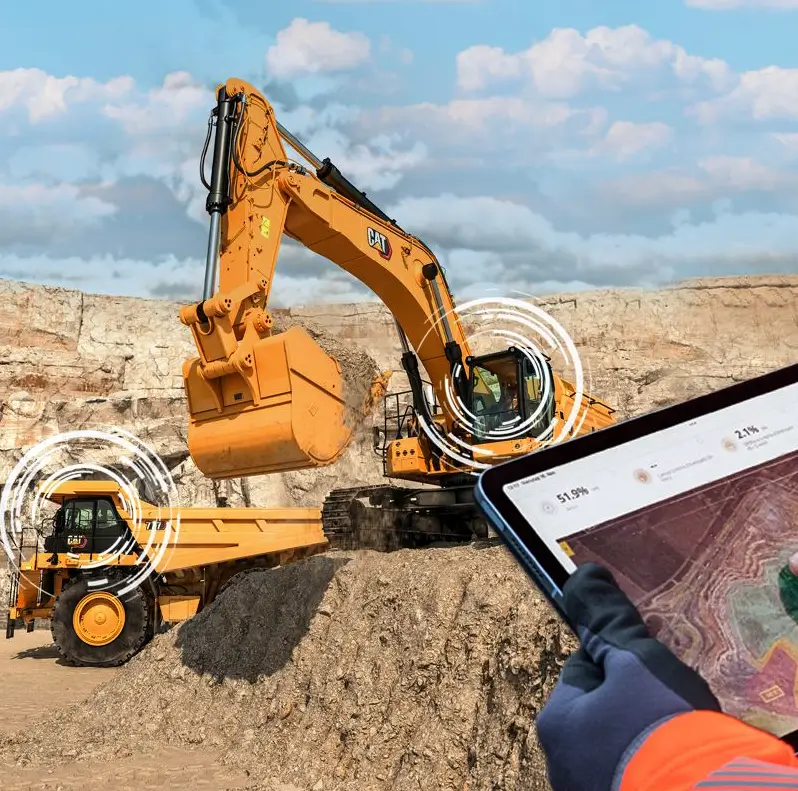

Condition Monitoring

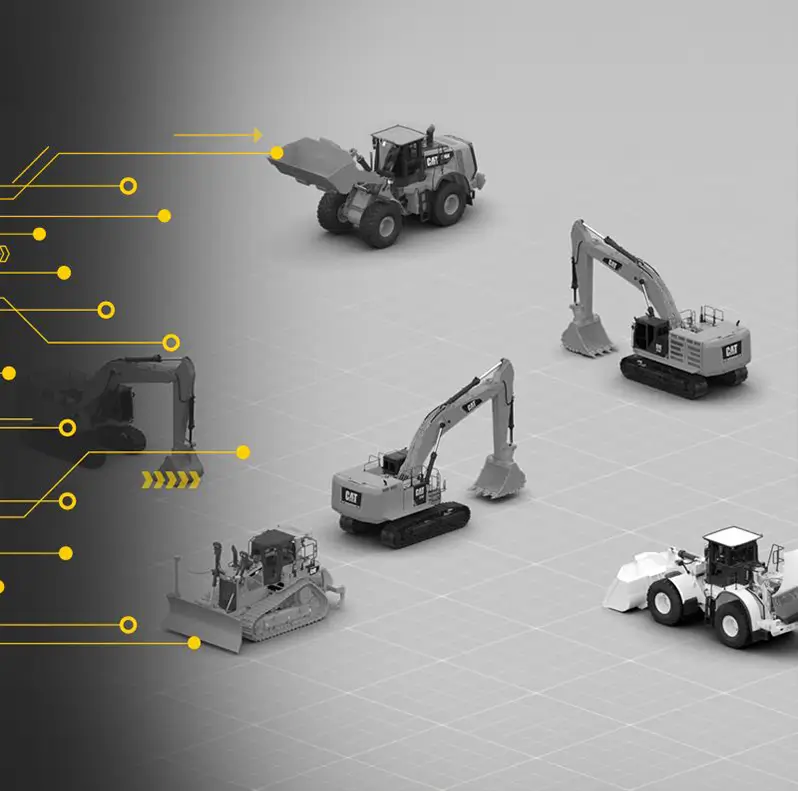

Monitor the health of your equipment with Cat® Condition Monitoring

Cat® Condition Monitoring is a data analysis service that helps you anticipate breakdowns, optimize maintenance and extend the life of your machines. By combining telematic data, maintenance history, fluid analysis and technical expertise, this service provides you with concrete recommendations for action before problems arise.

Move from reactive to intelligent preventive maintenance

Condition Monitoring vous permet de mieux comprendre le comportement de vos équipements. Grâce à une surveillance continue des performances et à l’analyse des tendances, vous identifiez les signes avant-coureurs d’usure ou de dysfonctionnement. Vous planifiez vos interventions de manière plus stratégique, réduisez les temps d’arrêt imprévus et maîtrisez vos coûts d’exploitation.

The benefits of Cat® Condition Monitoring

- Centralized monitoring of machine data (telemetry, maintenance, fluids, etc.).

- Early detection of anomalies and personalized recommendations.

- Optimization of maintenance schedules and after-sales resources.

- Reduce unplanned downtime and costly repairs.

- Better availability and longer equipment life.

- Support from Cat® technical experts to interpret data.

Our other services