It is difficult to overestimate the importance of preventive maintenance. Inspections, fluid analysis, oil and filter changes, and other preventive measures help keep your equipment in good working order and profitable.

But don't forget one key element: data. Not only does it enable you to detect problems at an early stage, but also to anticipate them before they arise. Thanks to digital diagnostics and predictive analytics, you can prioritize maintenance tasks and maximize the availability of your equipment.

Why is early diagnosis essential?

A small problem can quickly escalate. A clogged filter not only reduces a machine's efficiency; it can cause the engine to overheat and immobilize the equipment. A worn belt not only reduces power transfer; if it breaks, it can damage expensive components such as pistons and bearings, leading to complete failure.

Unexpected repairs and sudden breakdowns mean downtime, which delays your projects, puts pressure on deadlines, and can damage your reputation if you fail to meet your customers' expectations.

With planned maintenance, you can prevent problems from getting worse. And today, thanks to real-time predictive notifications, it's even easier to know which tasks should be prioritized.

Just-in-Time Maintenance

If you use equipment management software such as VisionLink® or Parts.cat.com, you already have access to up-to-date, customized data about your machines. Now, a new feature—service notifications—lets you receive actionable information directly on your mobile device.

These predictive alerts warn you of potential problems, such as a clogged filter or low coolant levels, allowing you to take action within minutes. And that's crucial, because predictive maintenance is more efficient: avoiding acting too early, too late, or too often saves time and money.

Solve Problems, Save Time

Service notifications do more than just alert you to potential problems. They also provide recommendations tailored to the specific needs of your equipment and connect you directly to the resources you need to resolve them.

For example, if you receive a notification that your backhoe loader is due for Level 2 maintenance in two weeks, you can immediately schedule this service with your dealer or order the necessary parts at parts.cat.com. Everything is automated, fast, and personalized for you.

Real-Time Diagnostics, Easy to Understand

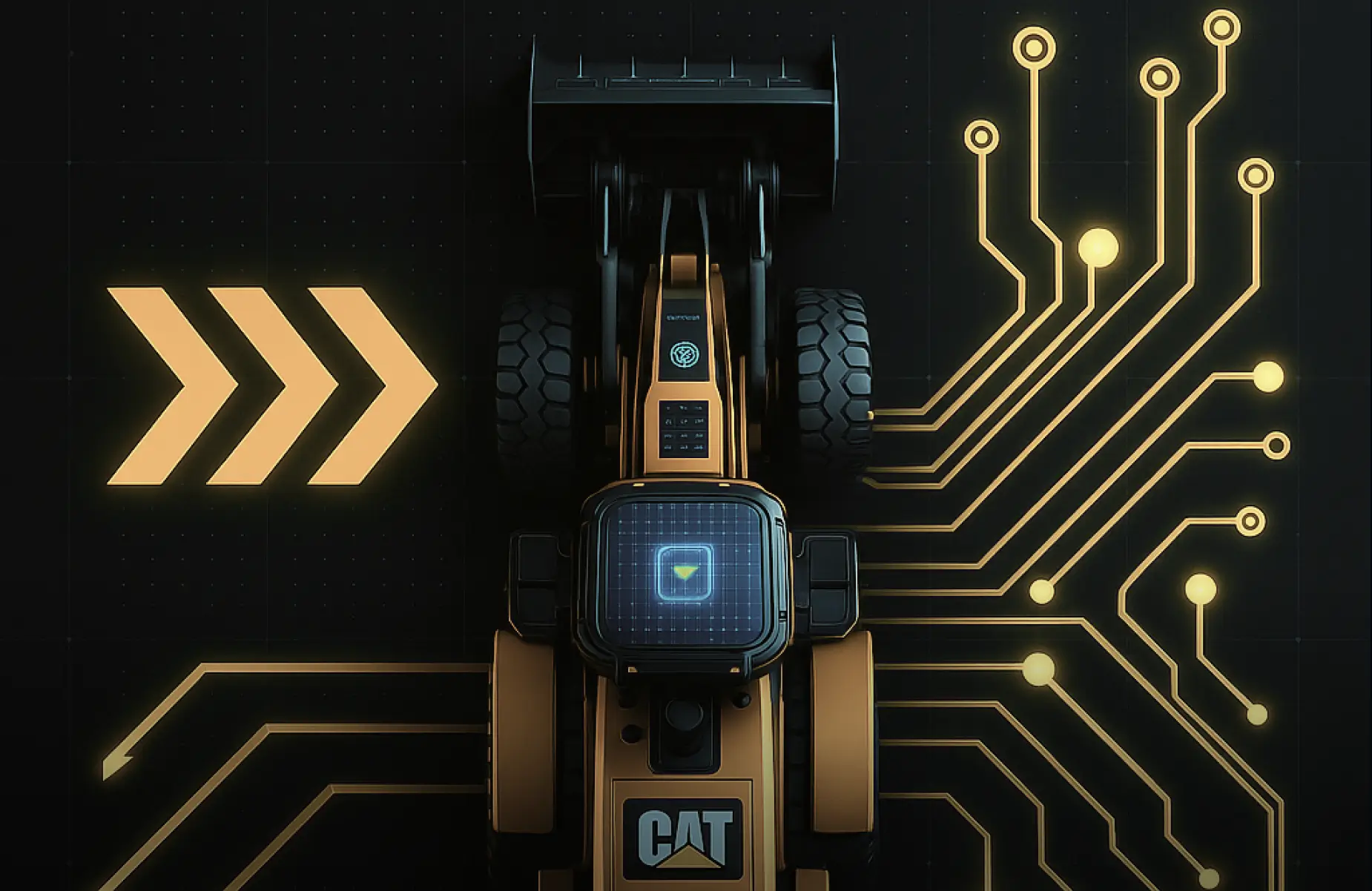

How does it work exactly? It's simple:

- Enable service notifications on VisionLink or parts.cat.com

- In the background, the technology continuously collects relevant data: telematics, fluid analysis, inspections, technical recommendations, maintenance history, etc.

- Thanks to artificial intelligence and machine learning, this data is analyzed in real time to predict critical events.

- When action is required, a notification will appear on your mobile device. Your dealer will also be notified so they can help you order parts or schedule a repair if necessary.

Worried about receiving too many alerts? Don't worry: you can adjust your notification preferences at any time in VisionLink or at parts.cat.com.

Reduce Downtime With Diagnostic Data

It's time to say goodbye to unexpected downtime by leveraging real-time predictive diagnostics. We're here to help.

Contact us starting today to activate service notifications on your devices.

Also worth discovering