Scale Studies

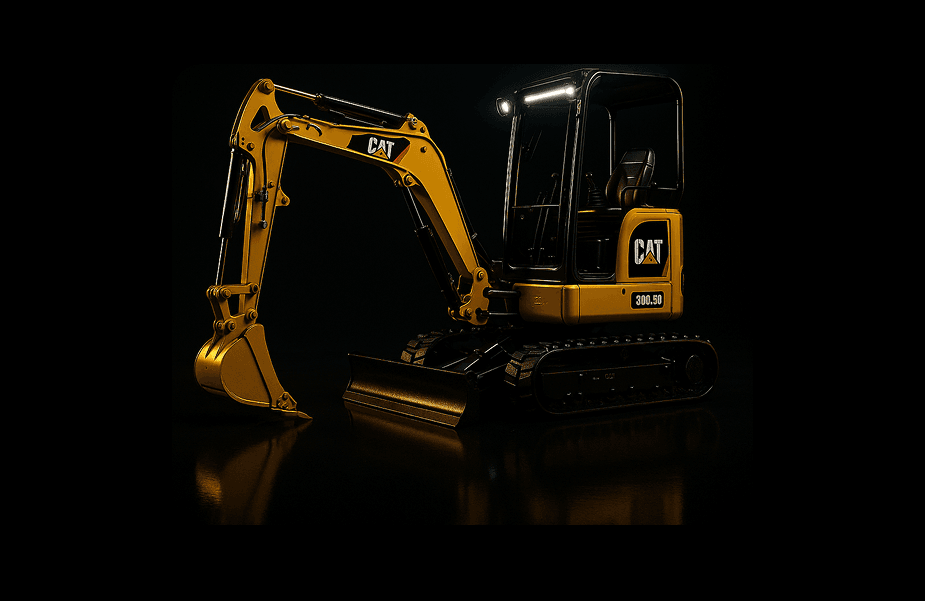

Precise loading for maximum performance

At Neemba, we collaborate with Caterpillar to help mining sites achieve their production goals while reducing costs. Using the Scale Study, we conduct an in-depth analysis of your loading and transport operations to ensure optimal payload for each cycle.

What we evaluate:

- Compliance with target loads for each type of truck.

- Presence of overload or underload.

- Impact of carryback (unloaded material).

- Calibration and reliability of weighing systems.

- Application of policy 10/10/20 recommended by Caterpillar.

Why conduct a weight study?

Every transport cycle counts. If your trucks are running empty or overloaded, you are losing money, wearing out your machines prematurely, and damaging your internal roads.

The Weighing Study allows you to:

- Optimize payload per cycle.

- Ensure the safety and longevity of your fleet.

- Reduce fuel consumption and CO₂ emissions.

- Improve the accuracy of on-board tools.

- Avoid costly unexpected repairs.

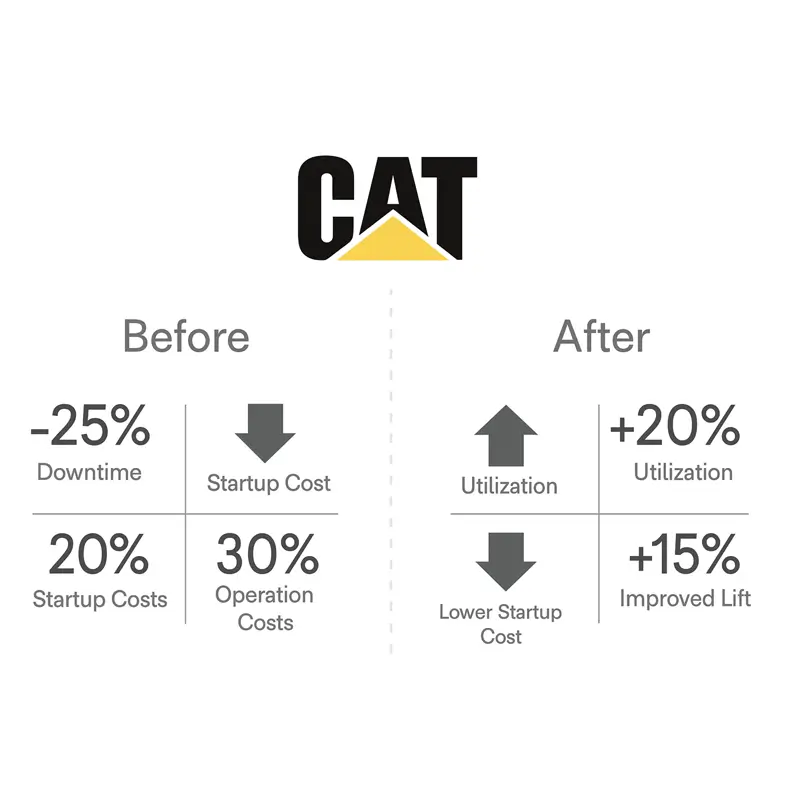

Your profits, right from the first shipments

- Maximizing production per truck.

- Validation and calibration of embedded systems.

- Greater energy efficiency per ton transported.

- Reduced maintenance costs and tire wear.

- Fewer unexpected stops, greater reliability.

- Extended equipment lifespan.

A precise field audit. Concrete results.

Nos experts procèdent à des études complètes sur site à l’aide d’outils de pesée professionnels, de balances et de scanners LiDAR. À la clé : un rapport détaillé, des recommandations pratiques et un plan d’action personnalisé pour atteindre vos objectifs de production, sans compromis sur la sécurité ni la durabilité.

Our other services