Tire Pressure Monitoring System

An onboard pneumatic control system on each machine

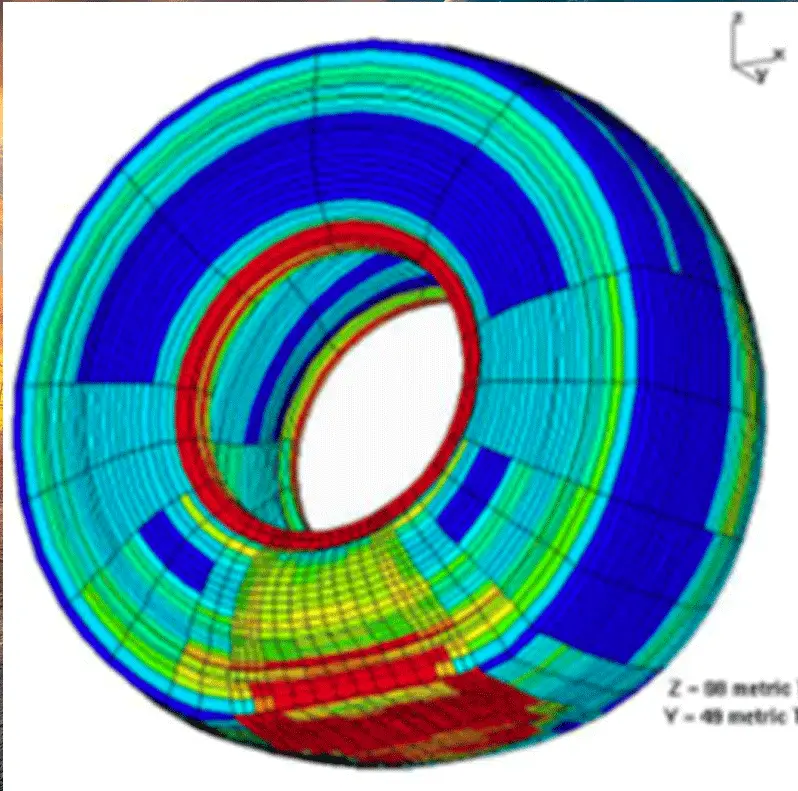

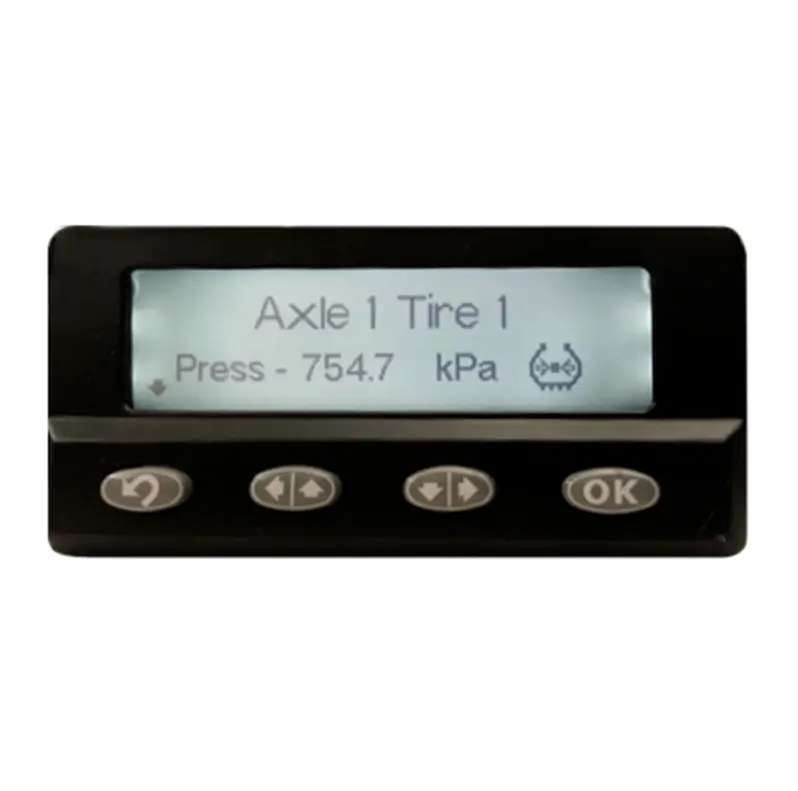

The TPMS measures pressure and temperature in real time as close as possible to the tire.

From in-cabin alerts warn the operator in the event of underinflation, overinflation, or abnormal heating; workshop teams receive clear reports to plan for reinflation, inspections, and rotations.

Every meter counts. Make every trip profitable.

An underinflated tire overheats, consumes more fuel, and wears out prematurely; an overinflated tire loses traction and absorbs more shocks.

The TPMS detects deviations early, guides corrections, and helps maintain the target pressure range according to load and cycle.

The result: more tons per hour, fewer blowouts, and greater operator comfort.

Tangible benefits for your productivity

- Up to several % in fuel savings thanks to controlled rolling resistance.

- Extended tire life (less heat build-up, even wear).

- Reduction in unplanned downtime and tire-related incidents.

- Protection of components (rims, suspensions, axles).

- Enhanced safety: more consistent braking distances and directional stability.

- Actionable reports for planning tire inflation, rotations, and budgets

TPMS — Tires at the heart of your operations

With TPMS, your maintenance decisions are based on factual data consolidated by machine, fleet, and site. The system integrates with your fleet tracking platforms for simple, quantified management.

- Dashboard: real-time pressure/°C, alarms, and history per wheel.

- Configurable thresholds according to application (load, speed, ambient temperature).

- Multi-channel alerts: cab, email/SMS, monitoring center.

- Traceability: incidents avoided, response time, tire cost per hour/ton.

- Exports for your operations and safety meetings.

Our complementary optimization solutions